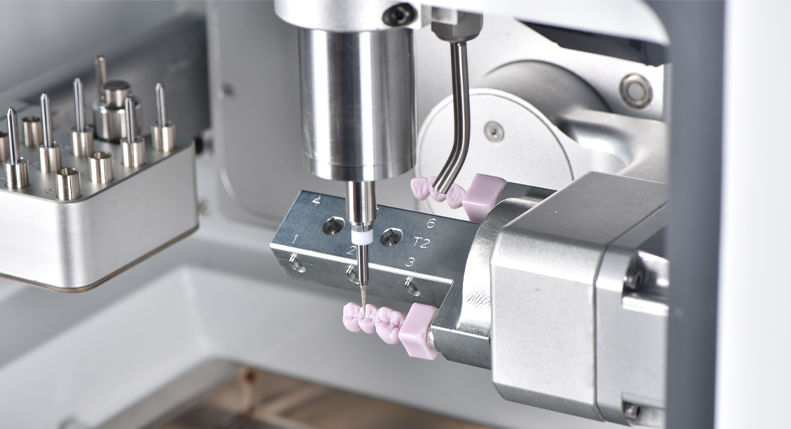

5-axis linkage, fine grinding

5-axis linkage cutting, suitable for fast processing beside the chair, can perform large-angle fine grinding, 0.1mm edge thickness, can ensure no cracking, cutting titanium columns is very accurate, saving labor

5-axis linkage cutting, suitable for fast processing beside the chair, can perform large-angle fine grinding, 0.1mm edge thickness, can ensure no cracking, cutting titanium columns is very accurate, saving labor

Can process a variety of common materials and prefabricated bases, can place up to 8 materials and 6 processing milling at the same time

Automatic circulating water system, integrated water level control, high precision

Material

Maximum freedom of indication

Fields of application:Wet machining

Materials:Glass ceramics, Titanium, Zirconia, PMMA, Composite materials

Indications:Veneers, Single crowns, Inlays, Bridges, Abutments, Telescopic crowns

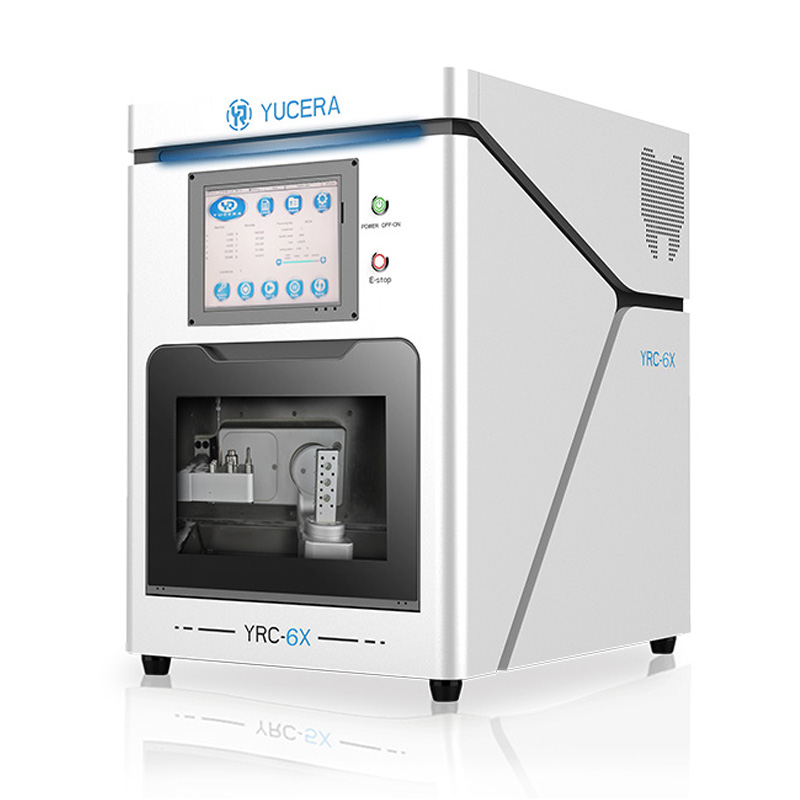

Machine bed made of solid cast aluminum body

Housing:Sheet steel housing, white high-gloss lacquer finish

Number of axes:5

Linear axes X-Y-Z-axis

Ground precision guides made of high-alloyed steel.

Rotary axis A-axis:Rotation angle360°, infinite.

Rotary axis B-axis:Precision ball screw with rotary transmission. Rotation angle: +20°

Lighting:RGB LED lighting with status display in the working chamber.

Operating temperature:Between 10℃ and 35℃

Air moisture:Max.80%(relative), non-condensing

5-axis linkage, Wet milling

Processing time:Full crown < 15 min, 3-unit bridge < 30 min

Processable material thickness:10-30 mm

Rated Working Pressure:6.0-7.5 bar (without water, oil-free).

Power:220-230 volts. 1.5 kw

Tool change

Tool magazine for 10 tools

Dimensions(W/D/H):535x655x720mm with open flap and drawer

Footprint (W/D):480x580 mm

Weight:170 kg

High-frequency spindle, synchronous with pneumatic tool clamping

Sealing air to prevent debris from entering

Speed:Up to 60,000 rpm

Power:Peak power (Pmax): 1500 watts. nominal power: 800 watts

All models:CE, VDE

North America model:UL, FCC

+86 18929399126

+86 18929399126 kaka.cao@yucera.com

kaka.cao@yucera.com