Why Is There Such a Big Difference in the Price of All-Ceramic Teeth? Can All-Ceramic Teeth Last a Lifetime?

2024-10-23

2024-10-26

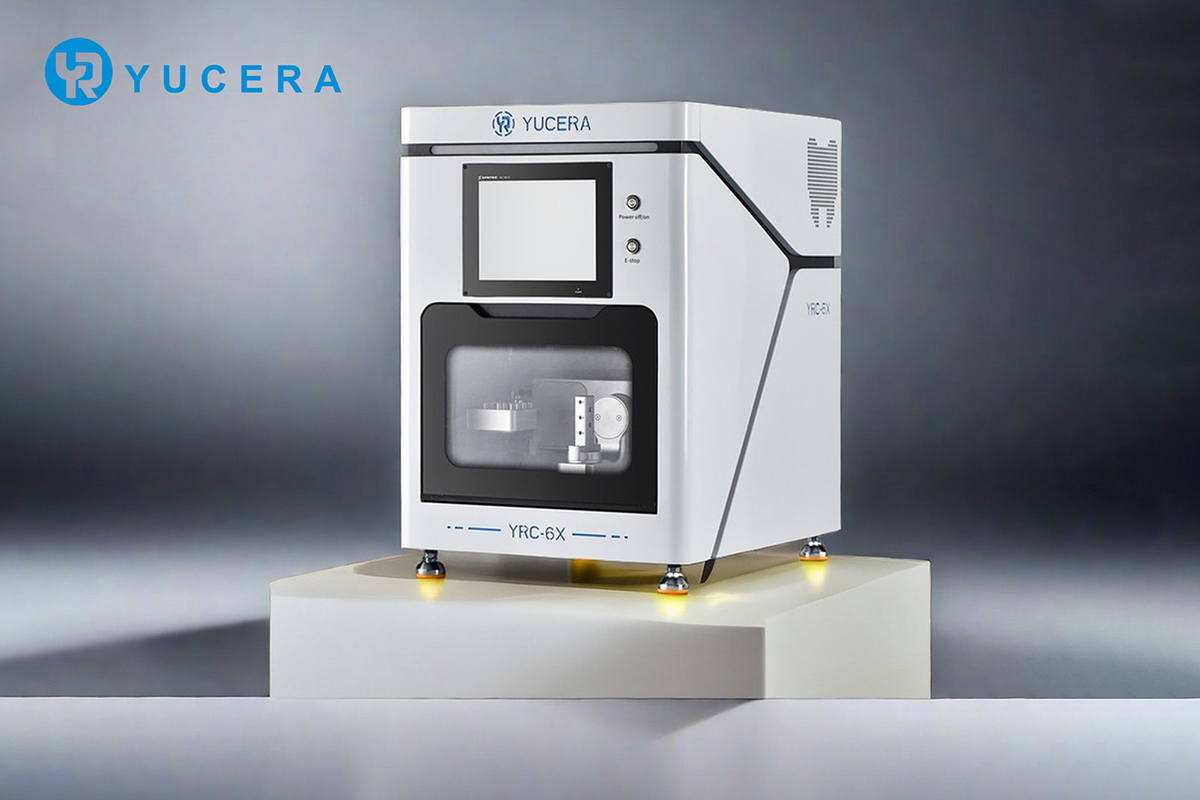

Dental milling machines are categorized into three types: dry, wet, and hybrid (dry-wet capable). Below is an explanation of their processing methods.

I. Dry Milling Machines

These machines operate without the use of water or cooling fluids, typically employing air cooling to cool the burs, clean materials, and check the cutting instruments.Mainly used for cutting soft materials (zirconia, PMMA, wax, PEEK, etc.), they usually employ burs with diameters around 0.6-2.0mm for processing.

II. Wet Milling Machines

These dental milling machines use water and cooling fluids during processing to suppress frictional heat while grinding.

Primarily used for processing hard materials (ceramics, titanium, etc.). The demand for hard materials is continuously increasing due to their strength and aesthetic appeal.

III. Hybrid Milling Machines

These models can perform both dry and wet processing methods.

The advantage is that a single machine can handle various materials, but there are drawbacks, such as the time required to clean and dry the machine when switching between dry and wet processing methods.

Additionally, there are often limitations in processing capabilities and higher initial investment due to the dual functionality.

IV. Pricing and Costs of Milling Machines

The price range for dental milling machines internationally can vary from a few thousand to hundreds of thousands of US dollars, depending on the type, functionality, brand, and configuration of the machine. Apart from the purchase price, consider the following costs:

- Peripheral accessories (dust collectors, air compressors, etc.)

- CAD/CAM software

- Milling materials

Click to learn more: /equipment/milling-machine/