Why Thousands of Americans Are Turning to Mexico for Dental Care

2025-03-20

2024-12-08

In the traditional dental process, patients need to lie in the dental chair for a long time, with the doctor to complete a number of complex steps such as taking moulds, adjusting and changing. This is not only inconvenient for the patient, but also a test of the doctor's technical level. However, with the rapid development of digital technology, the dental industry is now undergoing a revolution and new technology is changing the way we look at teeth.

This is the digital technology of chairside dentistry, where the doctor as well as the technician work in close collaboration next to the dental chair, making minimally invasive, precise and personalised oral treatments possible.

Are you curious about the steps involved from the moment you lie down in the dental chair to the creation of the final restoration?

Step 1: Digital scanning technology (digital impression)

With the digital intraoral scanner, a 3D model of your mouth can be quickly, accurately and completely taken in just a few minutes after the doctor has prepared the ‘abutment’ (the initial cleaning and restoration of decayed teeth).

This is the ‘first experience’ that patients usually have with digitisation. This is a much more efficient and comfortable way of obtaining a model than the traditional way of obtaining a model.

Next, the doctor continues treatment in the dental chair. At this time, the patient's intraoral data has been transmitted to the Dental Digital Centre, a unique technical support platform of the dental specialist hospital.

Here, a professional team of dental technicians will work closely with the doctor to complete a series of work from design to manufacturing of the teeth, helping the doctor to achieve the ideal treatment plan!

Step 2: Computer Aided Design and Manufacturing (CAD/CAM)

In the Dental Digital Centre, a variety of ‘black technology’ high-precision equipment is endless. Among them, the most commonly used in clinical practice, is the ‘chairside CAD / CAM system’.

For example, oral digital technology is widely used in minimally invasive restorations such as inlays and veneers. Commonly used dental restorative materials are porcelain and composite resin, which can strike a good balance between biocompatibility and aesthetics to meet the different requirements of patients.First, a team of professional technicians generates a 3D colour model of the patient's intraoral data and creates a personalised aesthetic design based on the doctor's treatment plan and the patient's needs.

Through the computer-aided design (CAD) technology, the parameters of ‘edge, neighbourhood and occlusion’ between the inlay and the abutment can be accurately controlled to design the ideal embryo.

After the design is completed, a dental restoration is quickly and accurately cut by a high-precision computer-controlled machining (CAM) system, and a dental restoration embryo is completed.

During this process, the design and presentation of the dental restoration is fully visualised. This visualisation not only facilitates efficient communication between the doctor and the technician, but also helps the patient to understand the treatment process and the expected results, and enhances their confidence in the treatment.

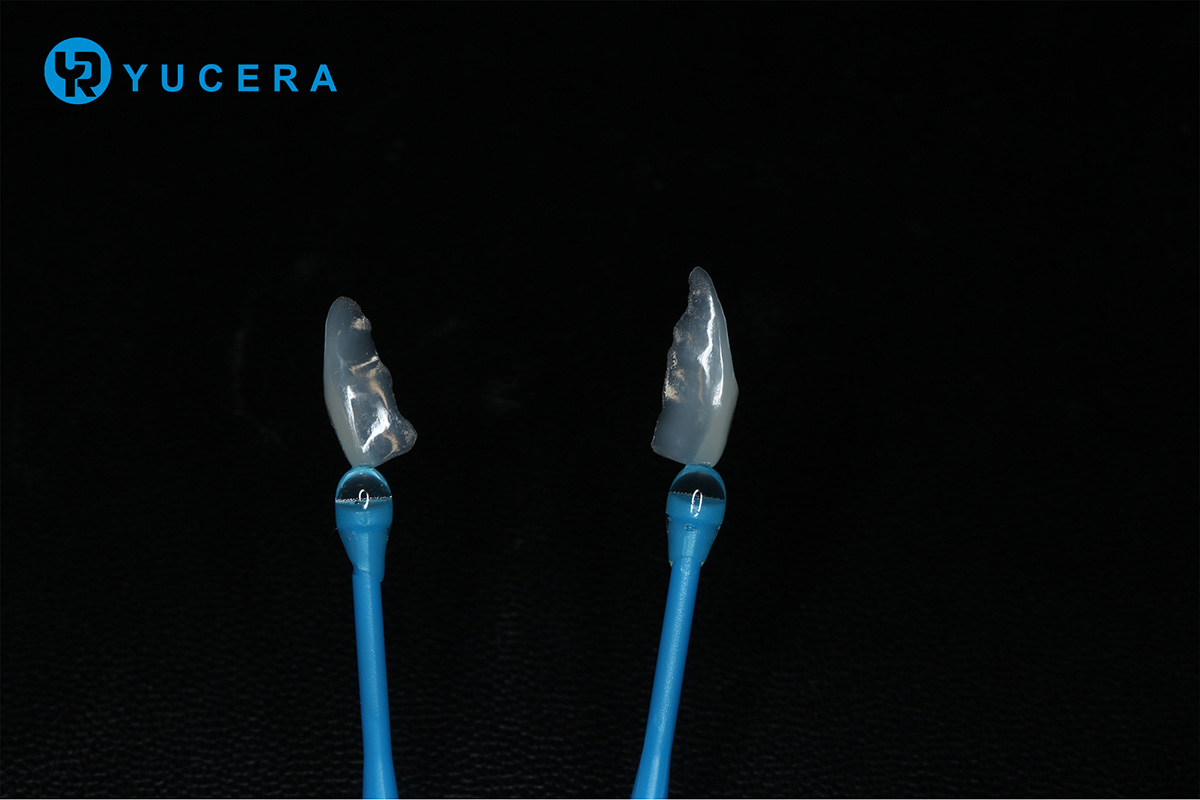

Step 3: The finished product - the final restoration

After the embryo has been processed, it still needs to go through a series of procedures such as fine-tuning, colourimetry, glazing and dyeing, sintering, etc., and be ‘injected into the soul’ through the craftsmanship of the technician's hands before the final restoration can be completed.

Compared to traditional techniques, chairside digital technology can produce an ideal dental restoration in as little as a few hours. Not only does it save patients time and cost, but it also improves patient engagement and trust.

For some complex and difficult patients who need oral treatment under general anaesthesia, this ‘masterpiece’ is the core technology to solve their dental difficulties, allowing patients to wake up and have completed all dental treatment!

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more