What is CAD CAM Used for in Dentistry?

2025-10-09

2026-02-04

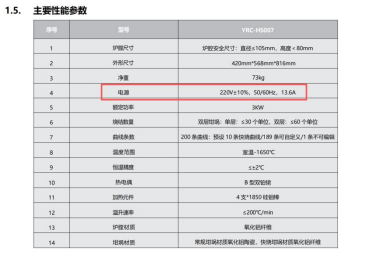

A: The "40-minute" rapid sintering refers to the temperature rise time of a single crown in YRC-HS007, excluding the natural cooling time.

A: The external voltage cannot be directly connected to 110V. A 10kW inverter can be used to convert the 110V voltage to 220V. (It is recommended that the transformer's power be greater than the sintering furnace's own power.)

A:The equipment must be effectively grounded during installation, as shown in the figure below.(*Grounding is an effective measure to protect equipment and personal safety and should not be ignored.)

A:If the sintering temperature of the sintering furnace is set to 1200℃, the actual working temperature of the furnace chamber is 1210℃. This is because the furnace temperature is increased by 10℃ at the factory. If you do not want this error, you can manually enter "-10" in the "Temperature Adjustment" setting.

A: During operation, the optimal operating temperature range is +15℃ to +35℃, which is recommended by our manufacturer. If the operating temperature is not reached, it will not affect normal use. However, long-term use in a high temperature and high humidity environment will damage the motherboard chips and may even cause a short circuit in the motherboard.

A:Prolonged exposure to high temperature and humidity can affect electrical components and the motherboard, potentially causing short circuits due to moisture absorption of the motherboard chips.

A:The actual heating rate is set based on the rapid heating curve of zirconia. 200℃/min is compatible with 90% of zirconia brands, but in practical applications, it is not necessary to reach a rate of 200℃/min. Moreover, operating the heating element and power supply system at full power at 200℃/min will greatly shorten the service life of the heating element. Therefore, it is recommended that customers set the equipment to a rate of 100℃/min.

A: When installing and wiring the equipment, a 4-square-meter wire is required.

A:The silicon molybdenum rod is guaranteed for three months or 100 uses.

A:The equipment is covered by a 12-month warranty (excluding consumables). Consumables include: furnace platform, sintering box, zirconium beads, and exterior paint.

Dry & wet milling for zirconia, PMMA, wax with auto tool changer.

learn more

High-precision 3D scanning, AI calibration, full-arch accuracy.

learn more

40-min full sintering with 57% incisal translucency and 1050 MPa strength.

learn more

40-min cycle for 60 crowns, dual-layer crucible and 200°C/min heating.

learn more

High-speed LCD printer for guides, temporaries, models with 8K resolution.

learn more